TIMBERSKIN

YEAR: 2013

AFFILIATION: UNIVERSITY OF BRITISH COLUMBIA

CONCEPT:

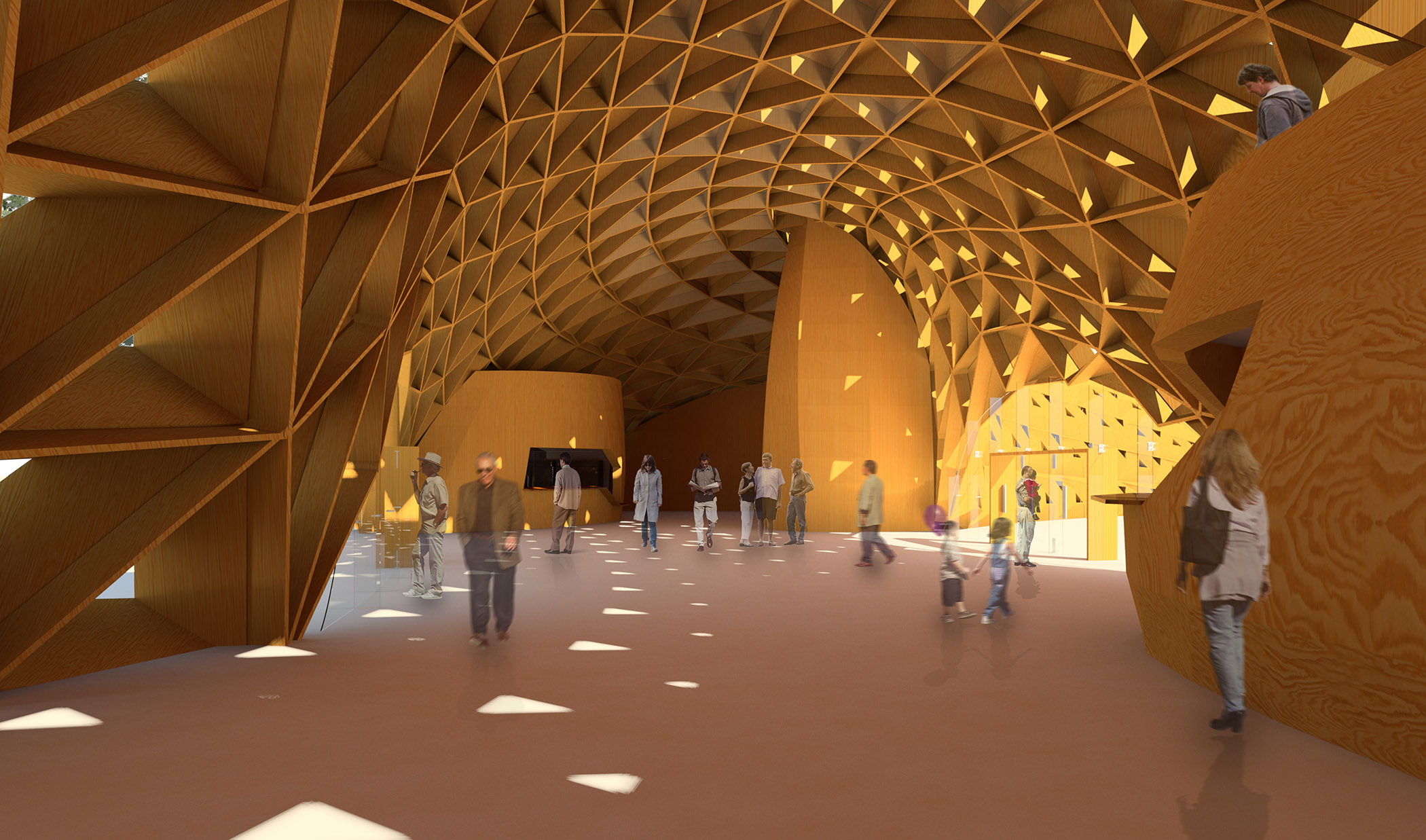

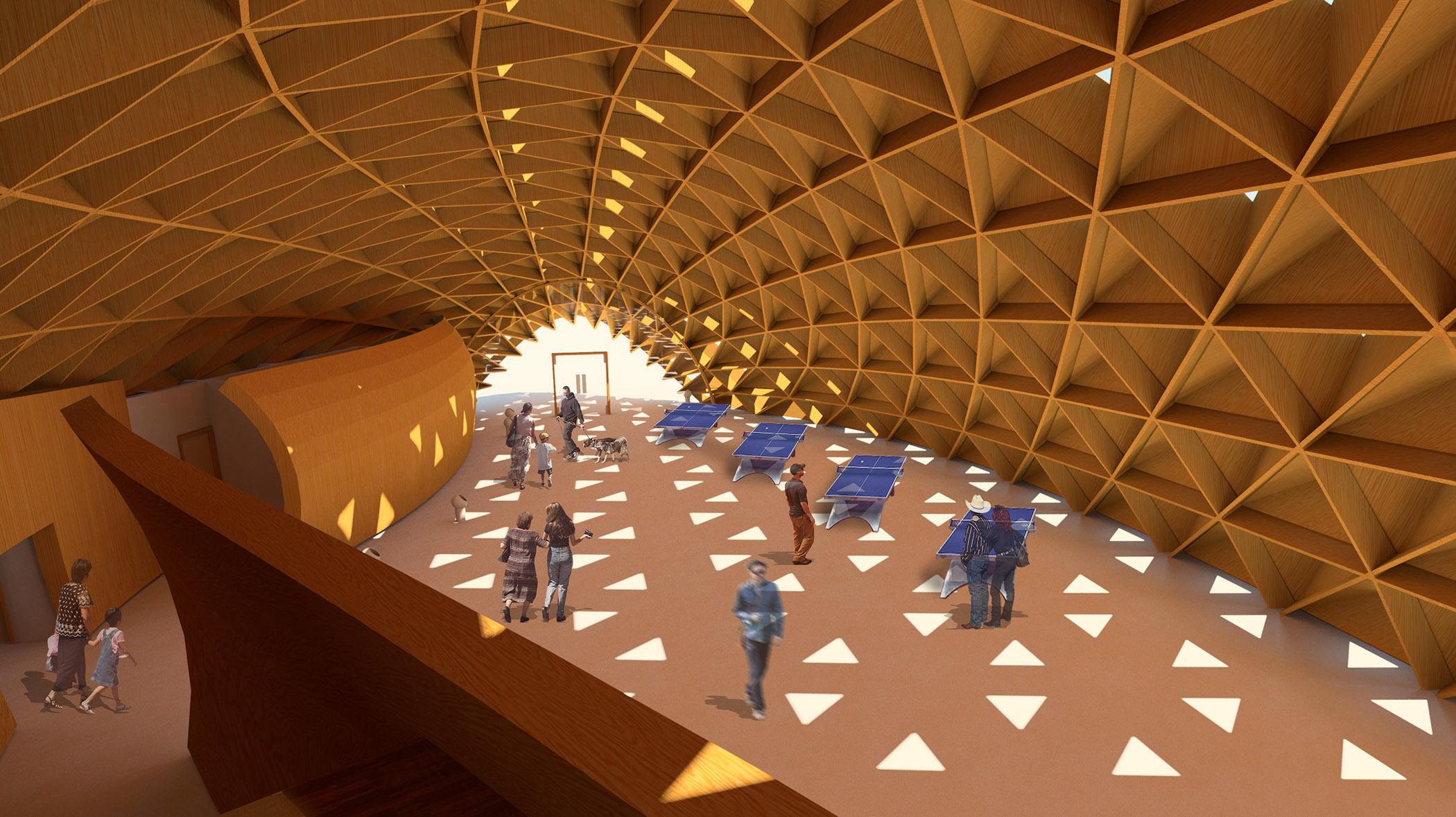

The goal of Timberskin was to create a structural system reliant entirely of advanced wood construction that goes beyond the standard conventions of traditional stick frame construction practice. By utilizing parametric design softwares such as Grasshopper, Galapagos, and Hummingbird it was the goal of the studio to create an adaptable and efficient system that could be adapted for numerous future iterations.

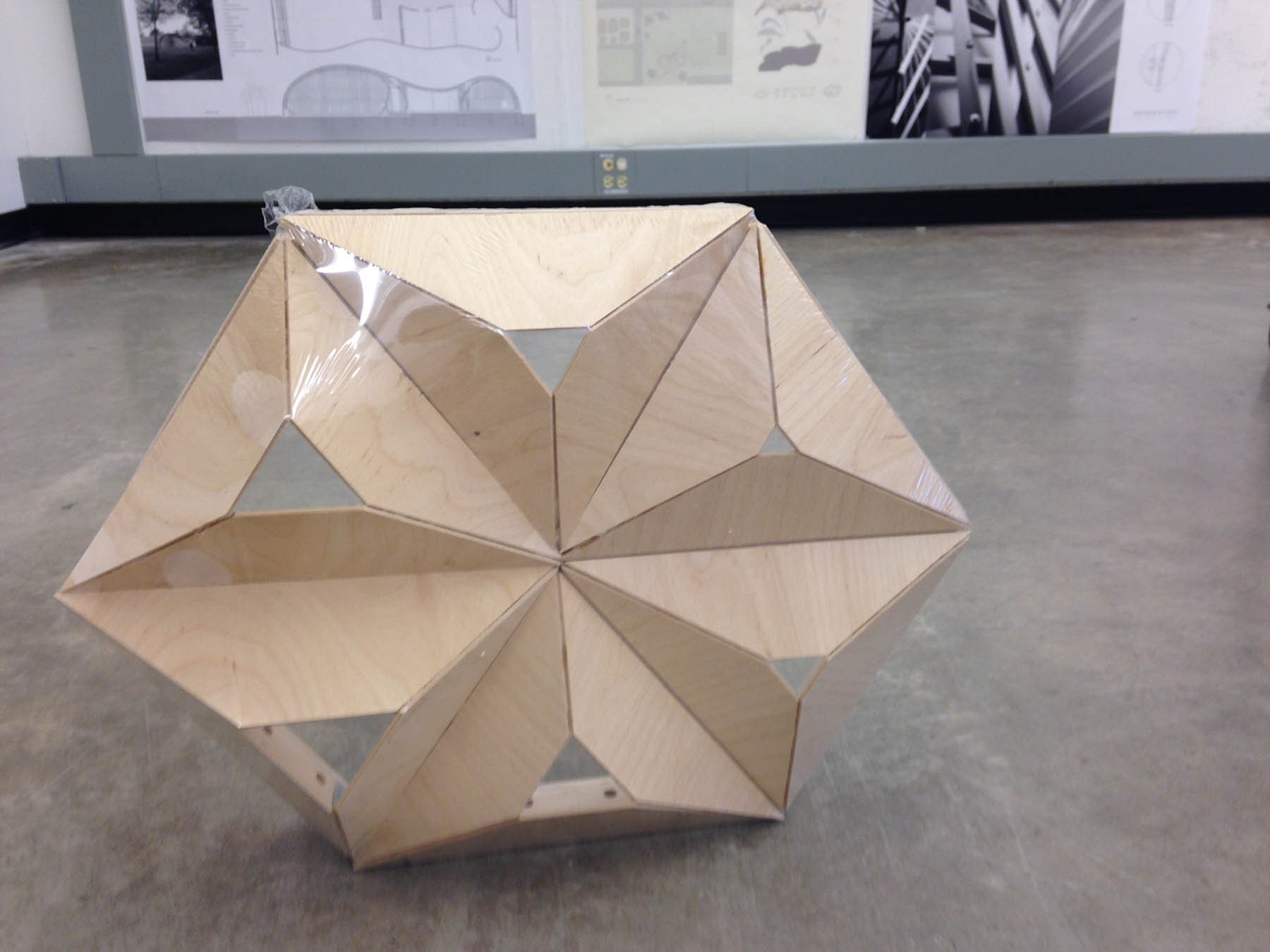

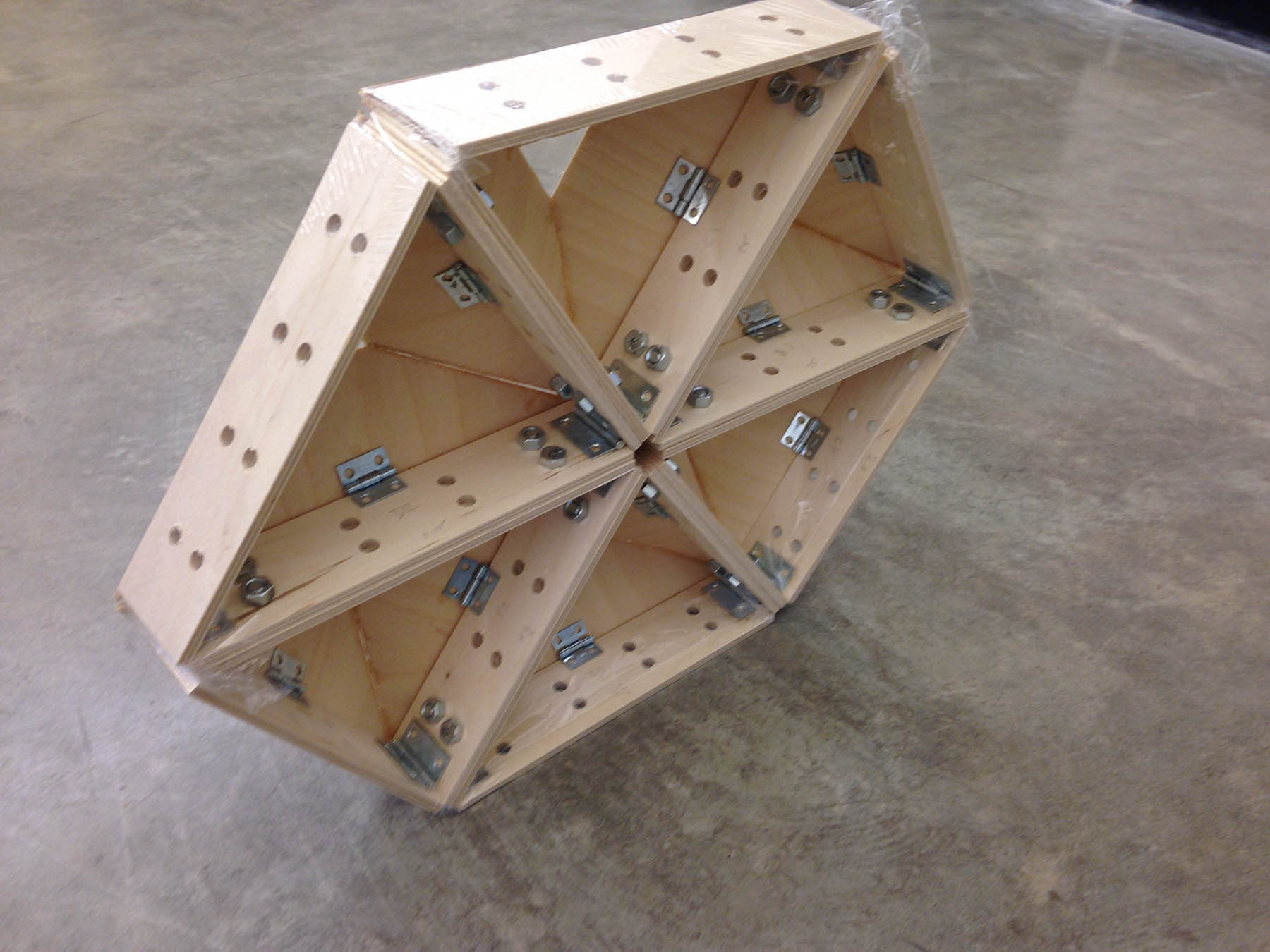

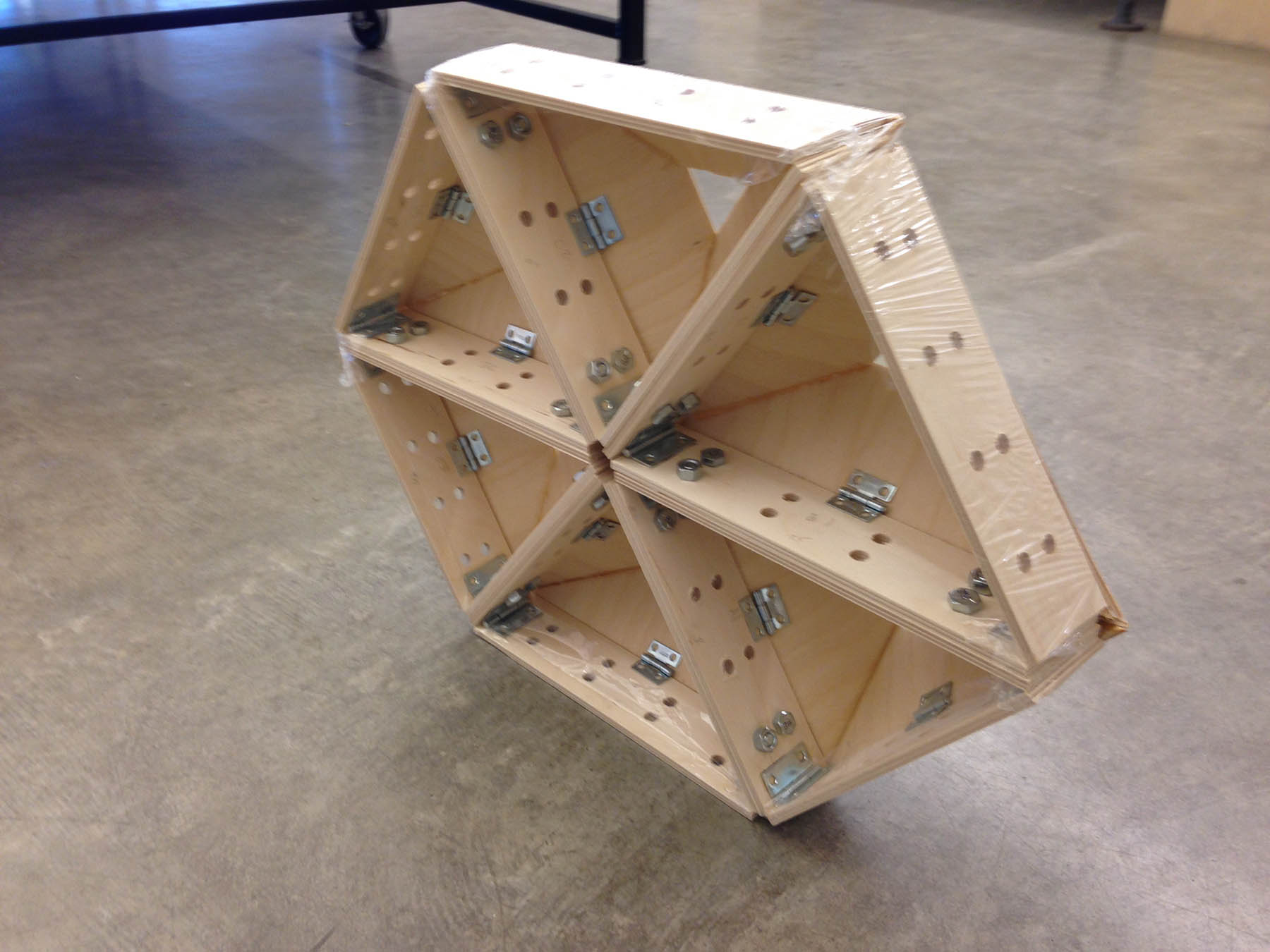

Working in conjunction with the University of British Columbia’s Center for Advanced Wood Processing we were able to explore the opportunities offered by parametric design and produce them in physicality with digital fabrication techniques, producing very complex geometries accurately as required by our exploratory structural methodologies.

Project aspirations:

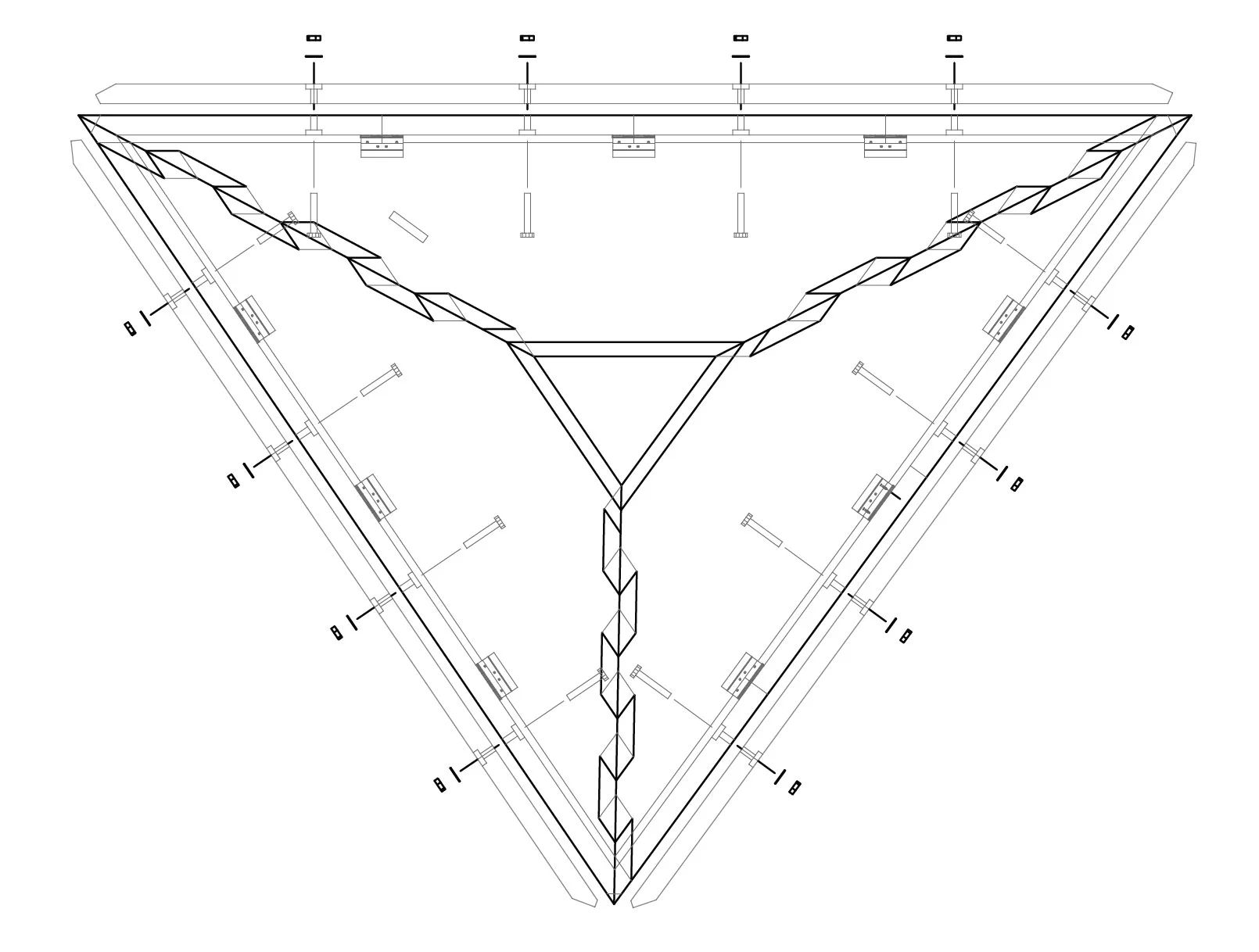

The goal of the project was to establish a stream line process from which various design requirements could utilize the resultant methodologies to create structures appropriate to the situation at hand. To accomplish this goal Grasshopper and various other open source plugins were utilized which could take a given number of inputs and limited variable parameters to create a structurally sound geometry.

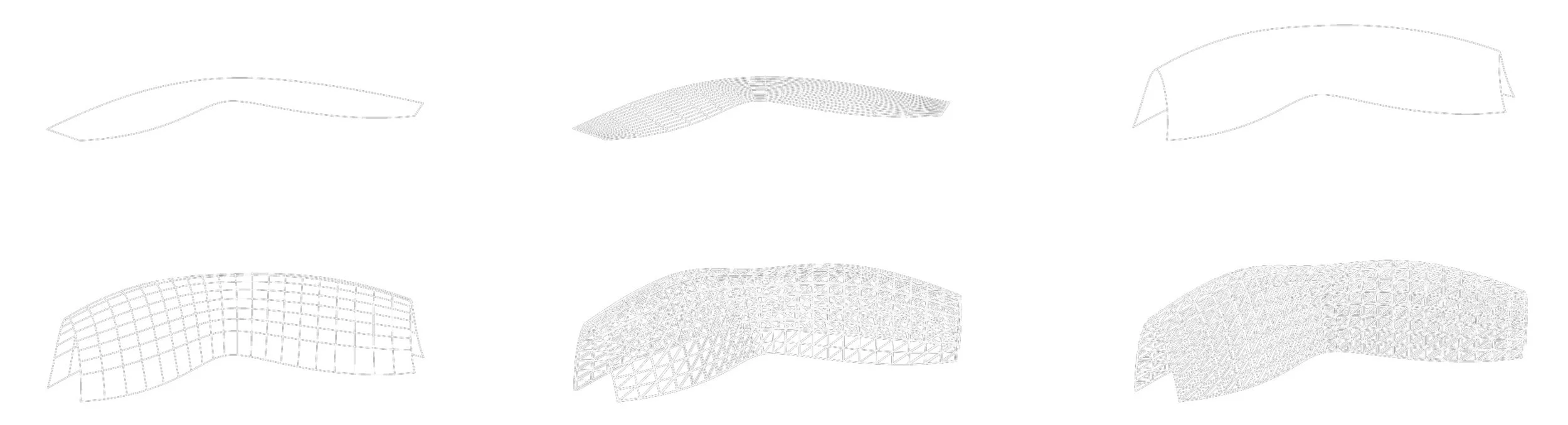

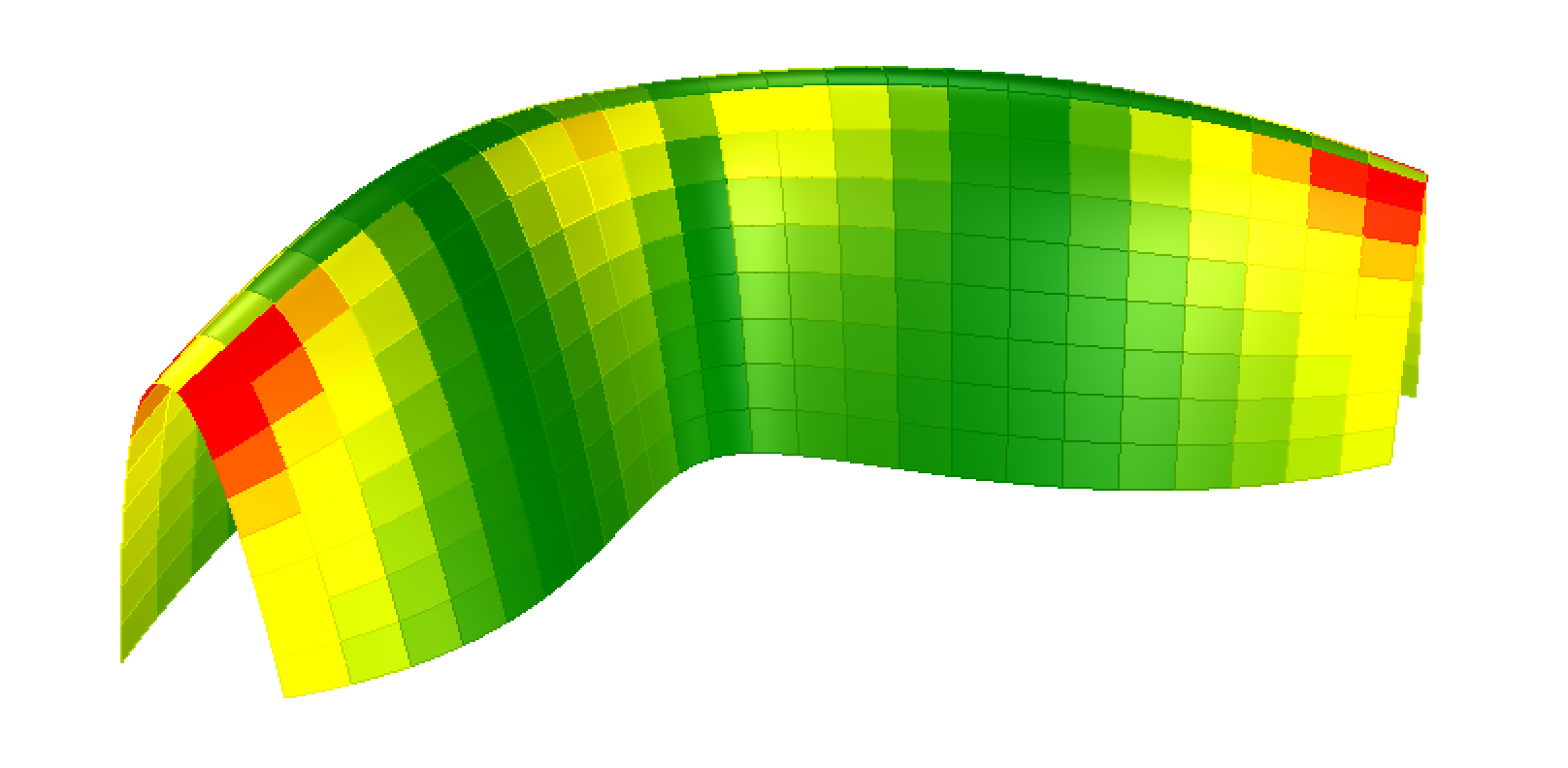

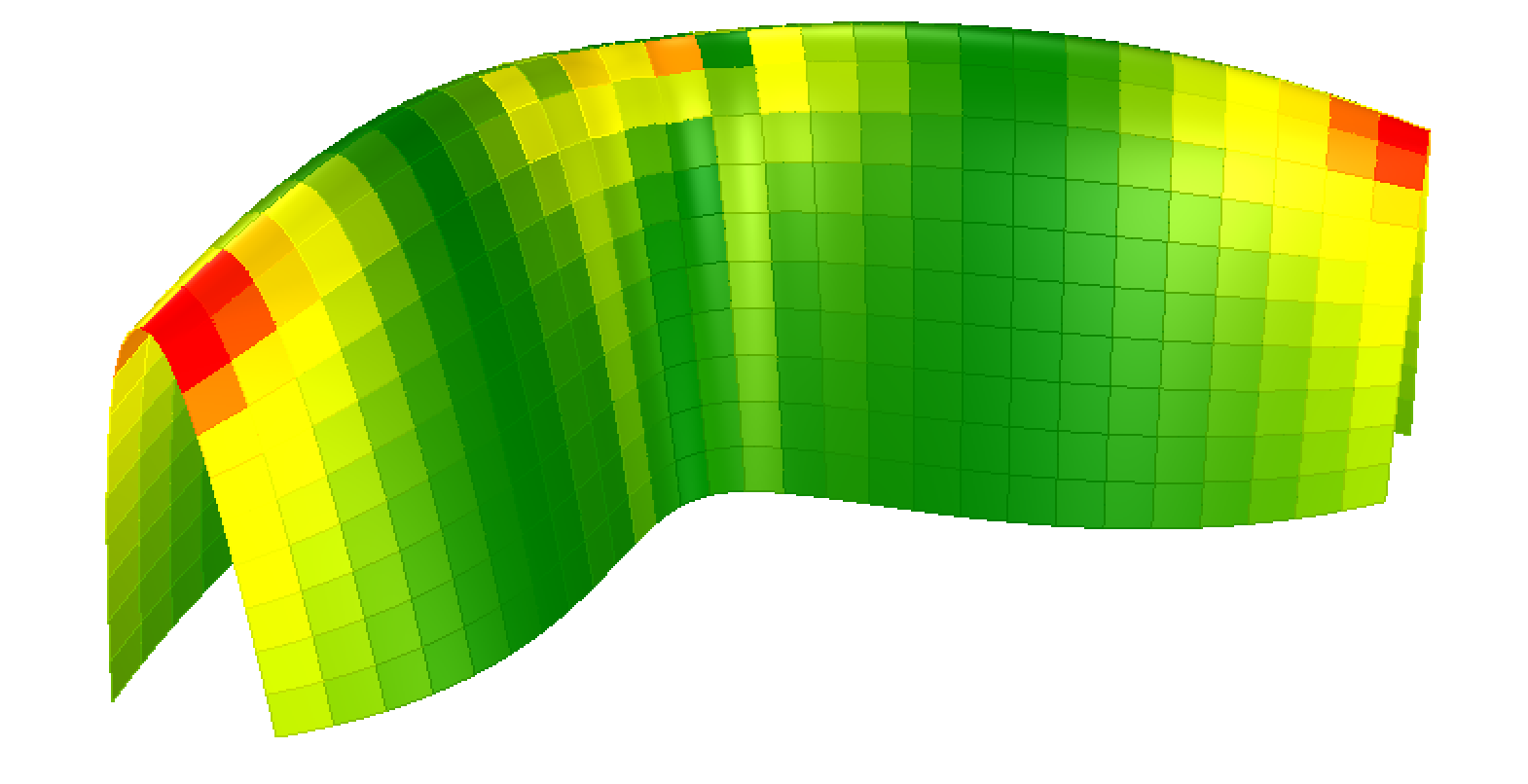

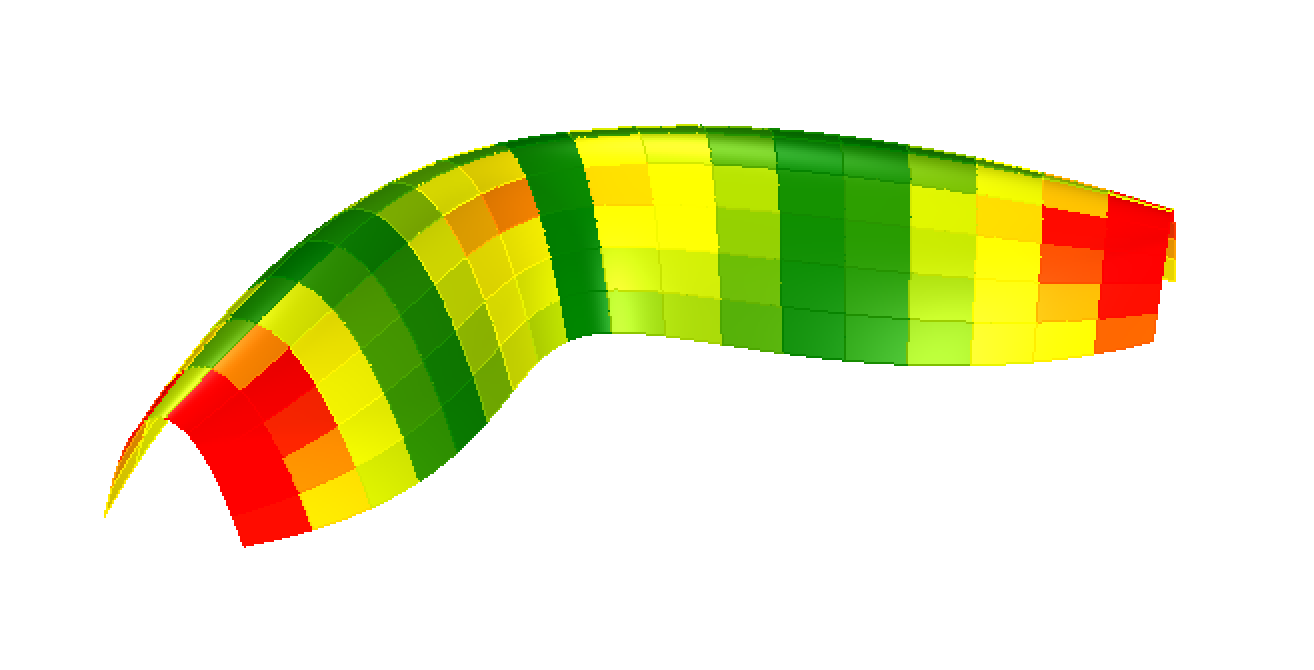

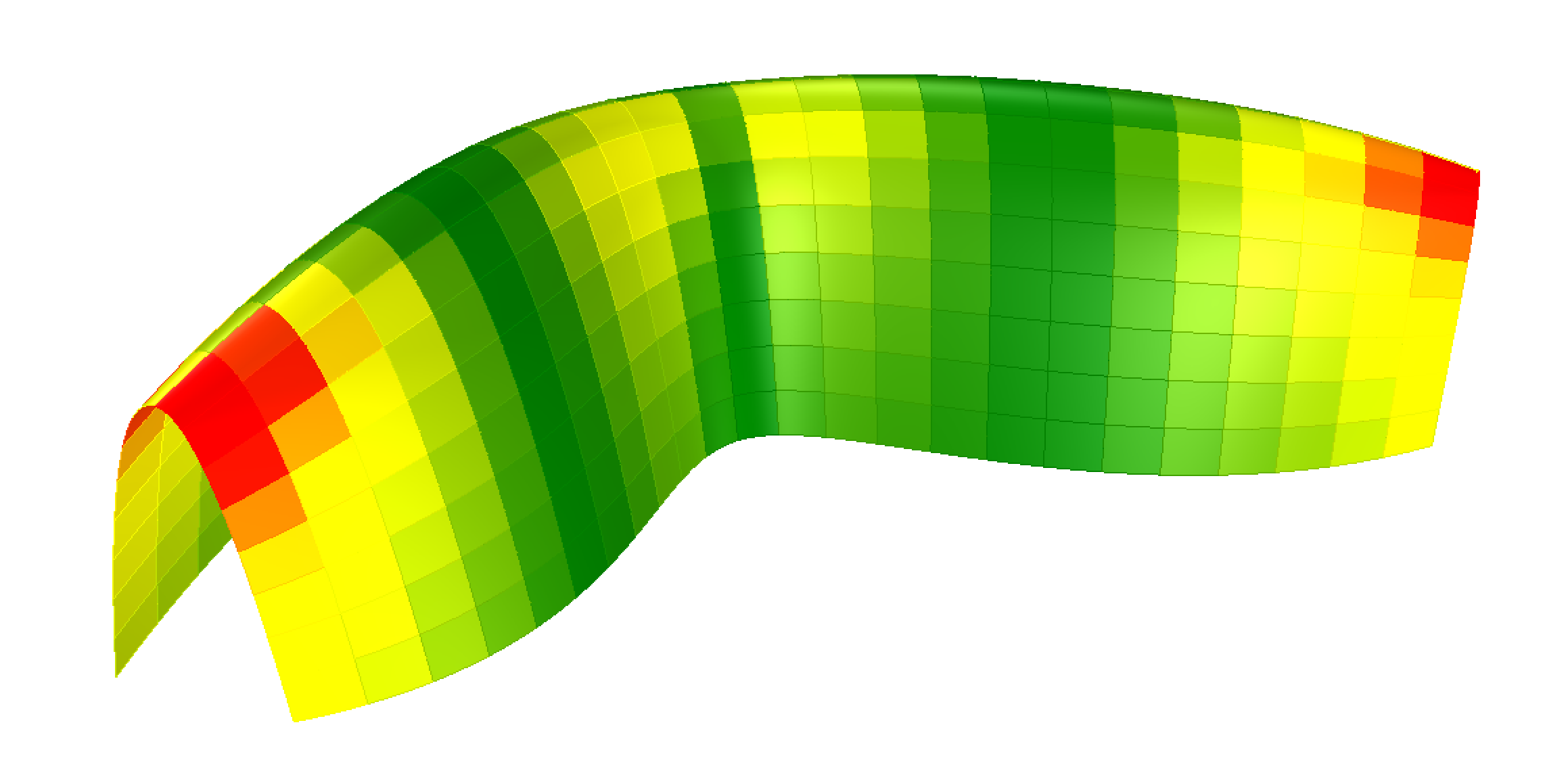

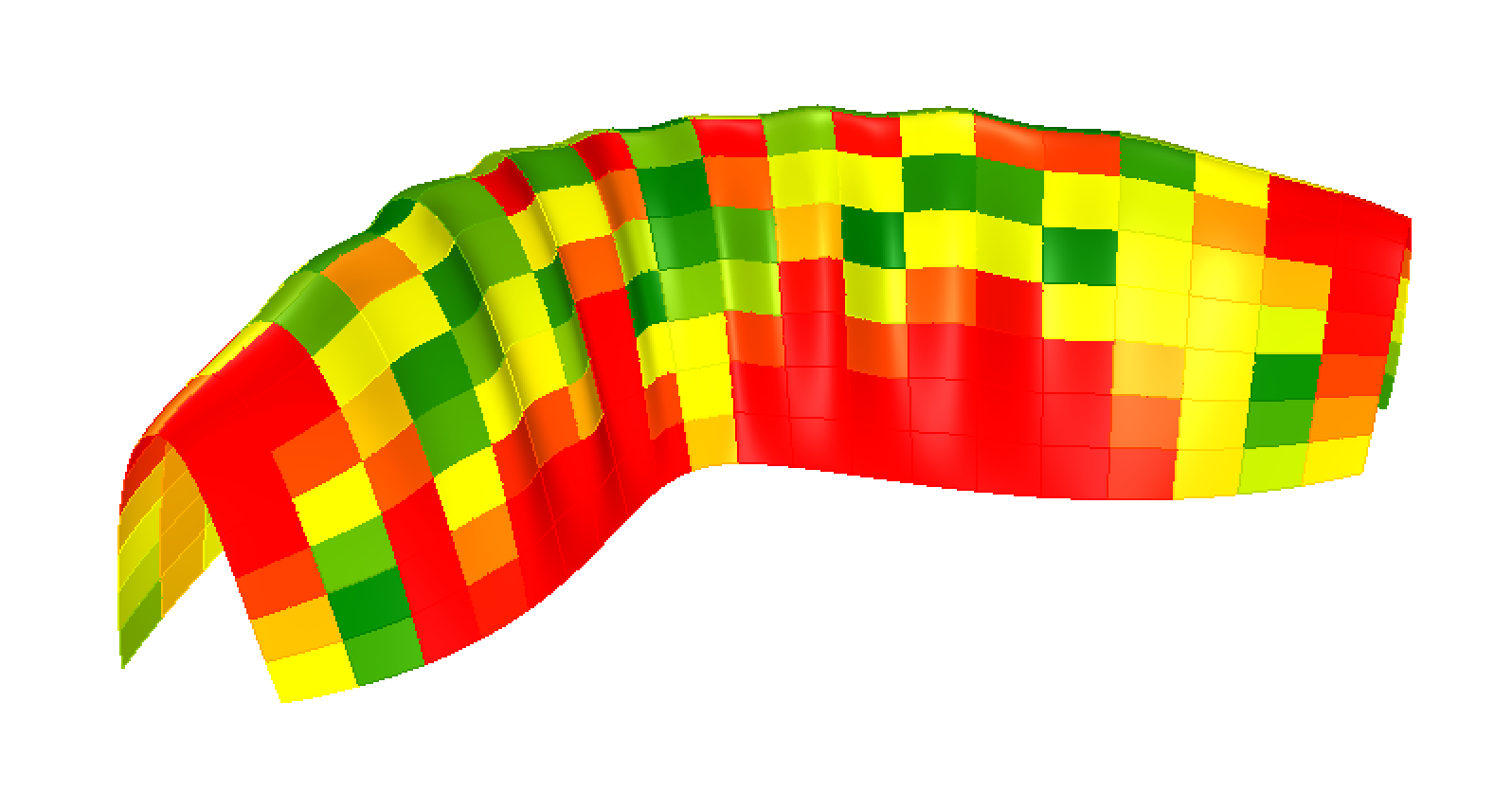

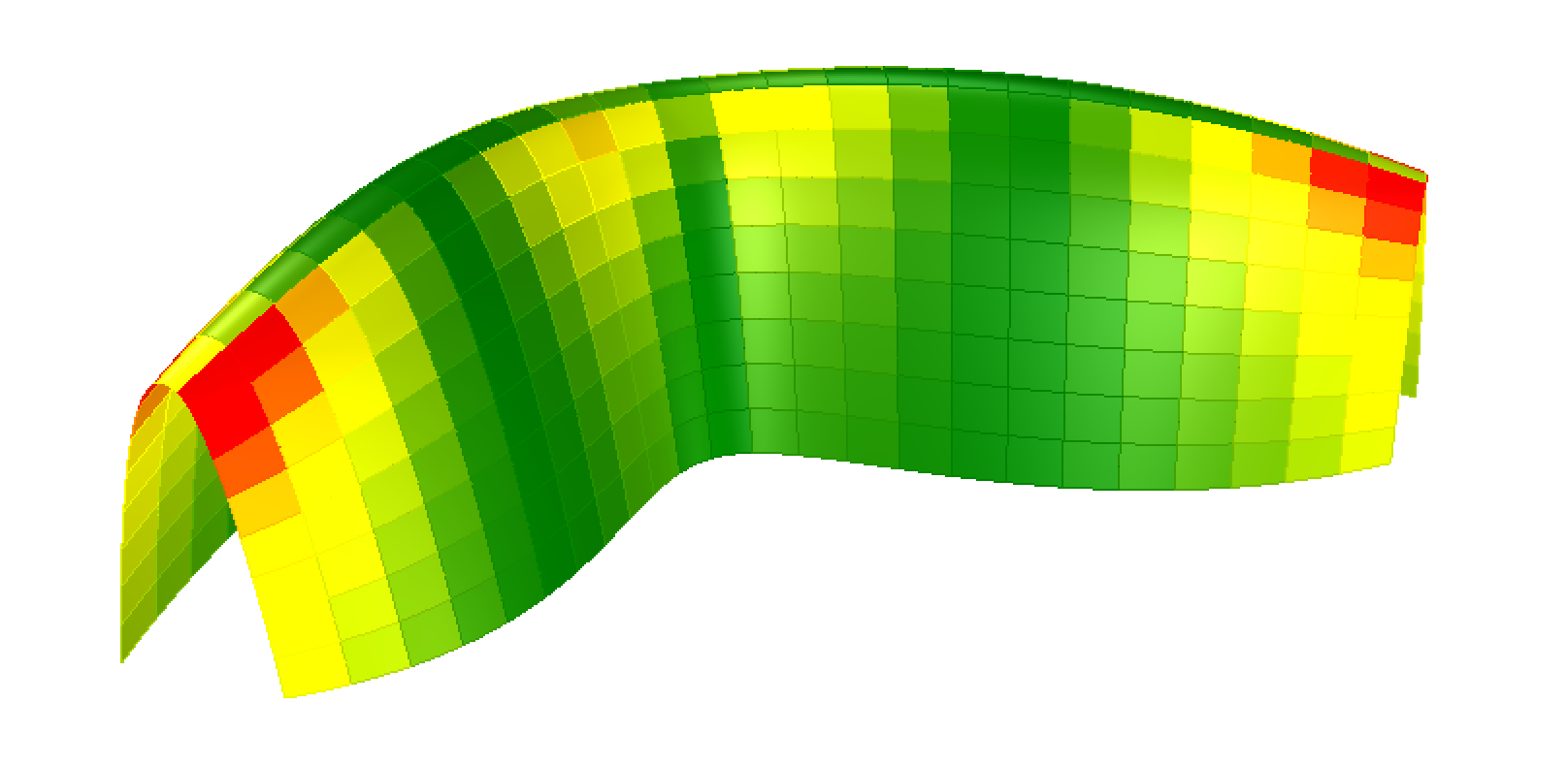

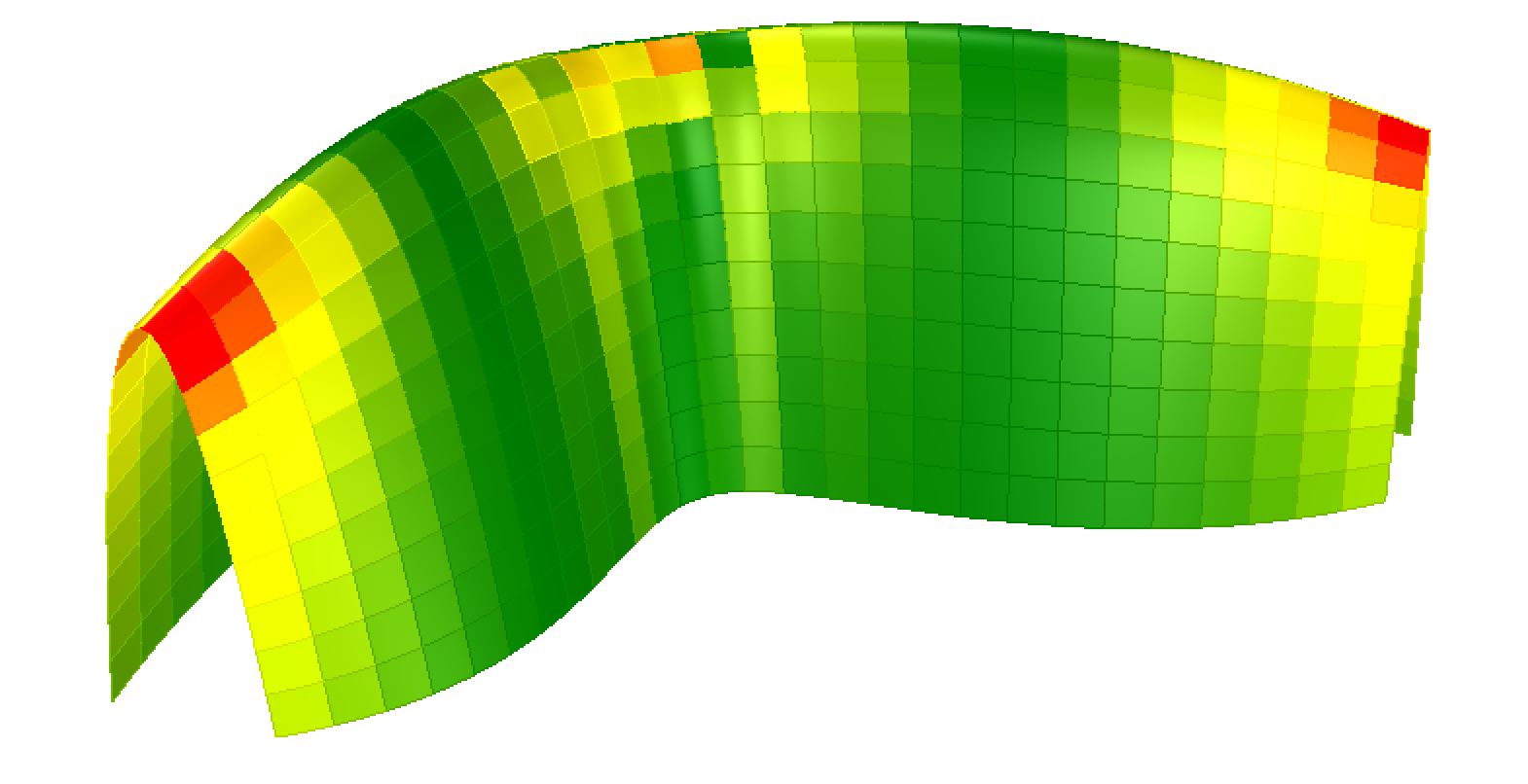

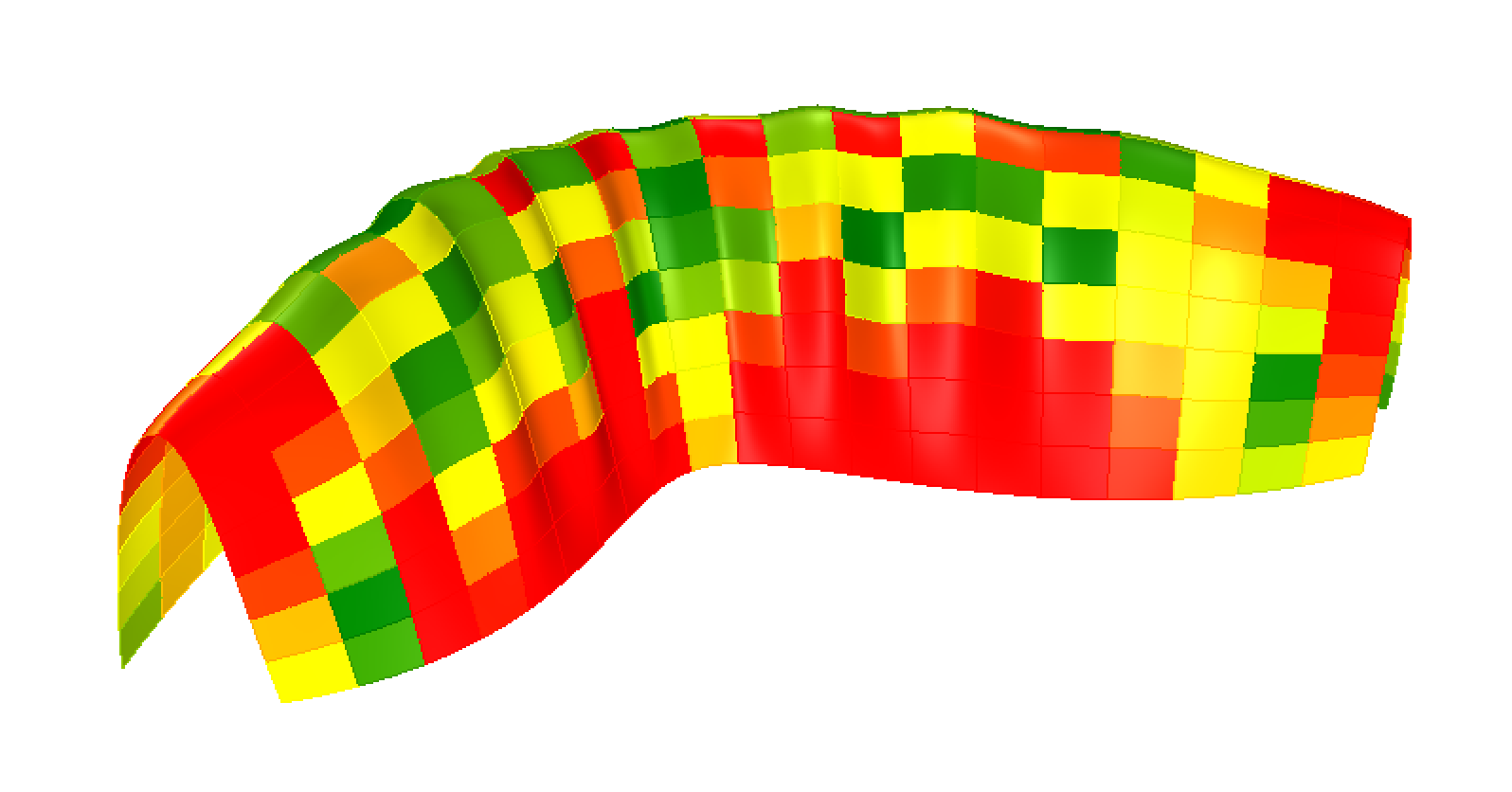

The resultant algorithms or scripts work in a matter that takes basic curves or other simple geometric data types and then applies forces to find an optimized form. The resultant form is then examined in a plug the Galapagos plugin which uses machine learning to examine various conditional outputs which alter the form to formulate an optimized surface of planar faces. After the optimized form is determined the surface is divided and reanalyzed for the population of its surface with modular apertures to control light and air across the structure. After this process the geometry is disassembled and nested for fabrication.

Materiality:

Evident from the project title the goal was to construct a timber shell with minimal supplemental materials to construct a self supporting structure. It was decided in the early phases of the project that the project needed to utilize sustainable resources when possible and limit materials by what can be easily ascertained and managed by a small manufacturer. Following this guideline a number of materials and systems are being considered. Engineered wood such as Oriented Strand Board or Cross Laminated Timber which from British Columbia were locally attainable.

Although the goal was to create a self sustaining timber shell it was decided from a realistic perspective that supplemental membranes were necessary in order create a lasting structure worthy of long term investment. To control water and vapor of the structure a heat sensitive membrane was proposed on the exterior which would flex and contour to the geometry of the shell.